Gate Valves: A Comprehensive Guide

Gate valves are crucial components used in various industries to control the flow of fluids in a pipeline system. Their design allows a full flow path when the valve is fully open, minimizing pressure drop. This comprehensive guide will explore the world of gate valves, including their features, applications, benefits, and considerations for selecting the correct valve for your needs.

What Are Gate Valves?

Gate valves are linear motion valves that control fluid flow by raising or lowering a gate or wedge within the valve body. When the gate is fully lifted, the valve allows for an unobstructed flow path while reducing the gate blocks the flow completely. This on/off operation makes gate valves ideal for applications requiring tight shut-off.

How Do Gate Valves Work?

Gate valves rotate a threaded stem or use a handwheel to move the gate up or down. The gate moves perpendicular to the flow direction, either fully opening or closing the valve. The rising stem design visually indicates the valve position, while non-rising stem gate valves are suitable for limited vertical space applications.

Critical Components of Gate Valves

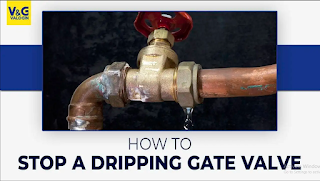

Gate valves have several key components, including the valve body, gate or wedge, stem, bonnet, seats, and packing. The valve body houses the gate and provides the necessary connections. The gate or wedge is the moving part that controls the flow. The stem connects the handwheel or actuator to the gate. The bonnet encloses the stem and provides a seal. The seats create a tight seal around the gate, and the packing prevents leakage along the stem.

Comments

Post a Comment