Shut-off Valve: Controlling Fluid Flow

Shut-off valves are essential components in plumbing systems that enable the precise control and regulation of fluid flow. These valves play a critical role in isolating sections of a plumbing system and shutting off the flow when necessary. In this article, we will explore the various aspects of shut-off valves, including their types, applications, advantages, installation process, maintenance, and more. Let’s dive in and discover the world of shut-off valves!

Introduction

In plumbing systems, shut-off valves act as gatekeepers, allowing or restricting the passage of fluids such as water or gas. These valves are strategically placed throughout the system to provide control and convenience. One common type of shut-off valve is the angle shut-off valve, which offers a compact design and efficient performance.

What is a Shut-off Valve?

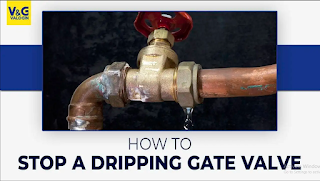

A shut-off valve is a plumbing fitting designed to control the flow of fluid through a pipe or tubing. It is typically placed in a section of the plumbing system where the flow needs to be controlled or shut off completely. Shut-off valves are crucial for emergencies, repairs, or when specific areas of the plumbing system require isolation.

Types of Shut-off Valves

Angle Shut-off Valve

The angle shut-off valve, also known as the corner valve or angle stop valve, features an L-shaped body with an inlet and outlet positioned at a 90-degree angle. This design allows for easy installation in tight spaces, such as behind sinks or toilets. Angle shut-off valves are commonly used in residential plumbing systems.

Ball Shut-off Valve

The ball shut-off valve utilizes a spherical disc (the ball) with a hole in the middle to control the flow of fluid. When the handle is turned, the ball rotates, allowing or blocking the passage of fluid. Ball shut-off valves are highly reliable, durable, and provide excellent flow control. They are commonly used in both residential and commercial plumbing systems.

Comments

Post a Comment